- Capabilities

-

-

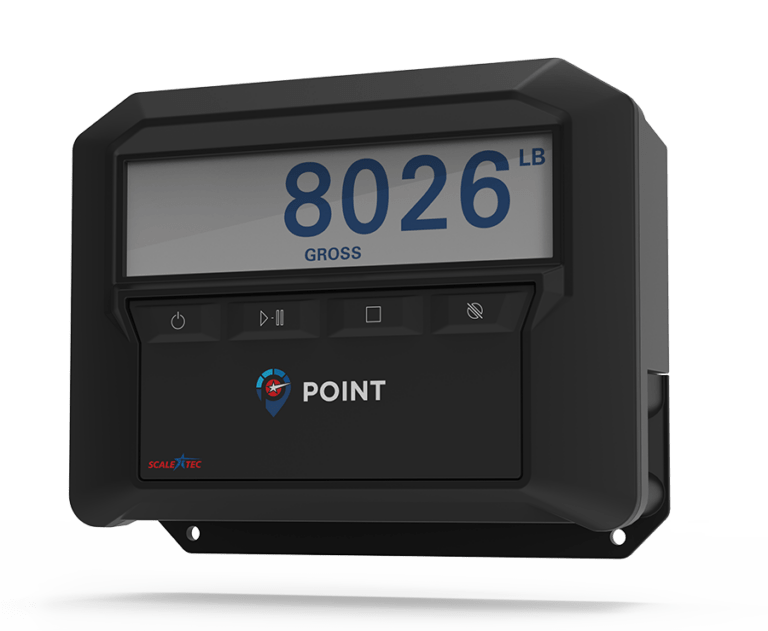

- Electrical EngineeringElectronic systems, PCB layout, integrated circuits, wireless communication, sensor design

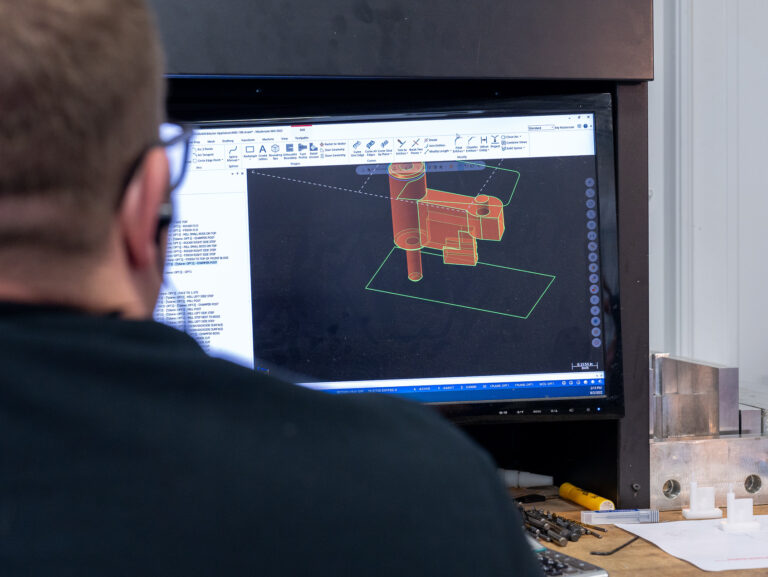

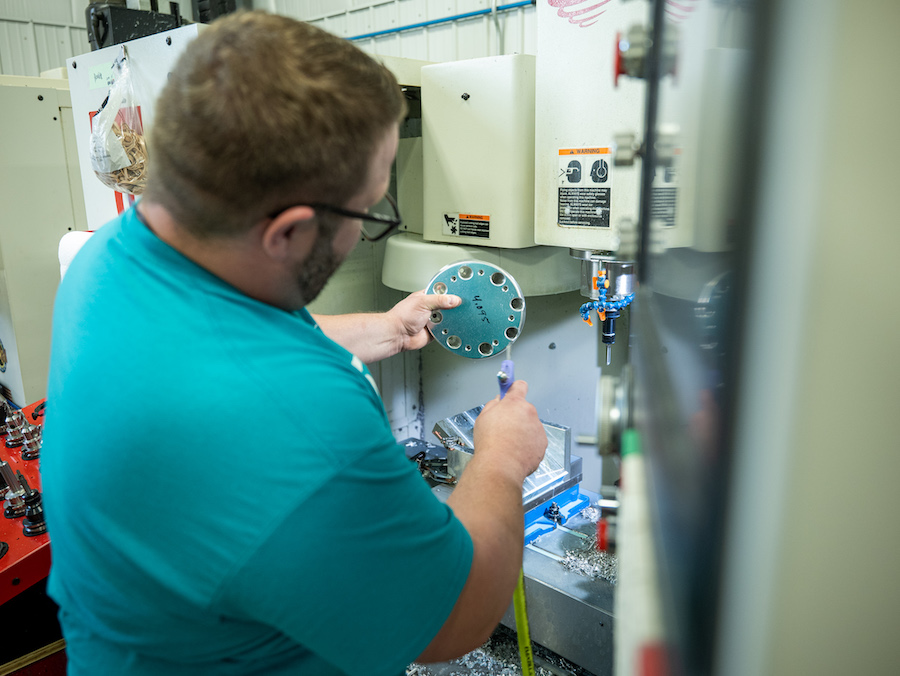

- Prototyping3D printing, cast urethane, cast silicone, metal fabrication, CNC machining, painting & finishing

- Testing & Quality AssurancePrototype validation, quality control, test fixtures, life cycle testing, Software Quality Assurance (SQA)

-

- UX & UI DesignWireframing & design, usability testing, design systems, interactive prototyping

- Software DevelopmentAndroid & iOS apps, cloud architecture, front-end & back-end development

- Embedded Software & Firmware DevelopmentEmbedded systems architecture, RTOS design, microcontrollers, embedded Linux, IoT connectivity

-

- Projects & Case Studies

- About Us

- Careers